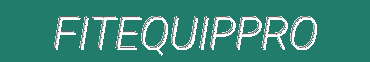

Servos are essential components in RC (radio-controlled) modeling, used to control various functions such as steering, throttle, flaps, landing gear, and more. They are electromechanical devices that convert electrical signals into precise mechanical movement, allowing remote control of different parts of an RC vehicle or aircraft.

Key Characteristics and Features:

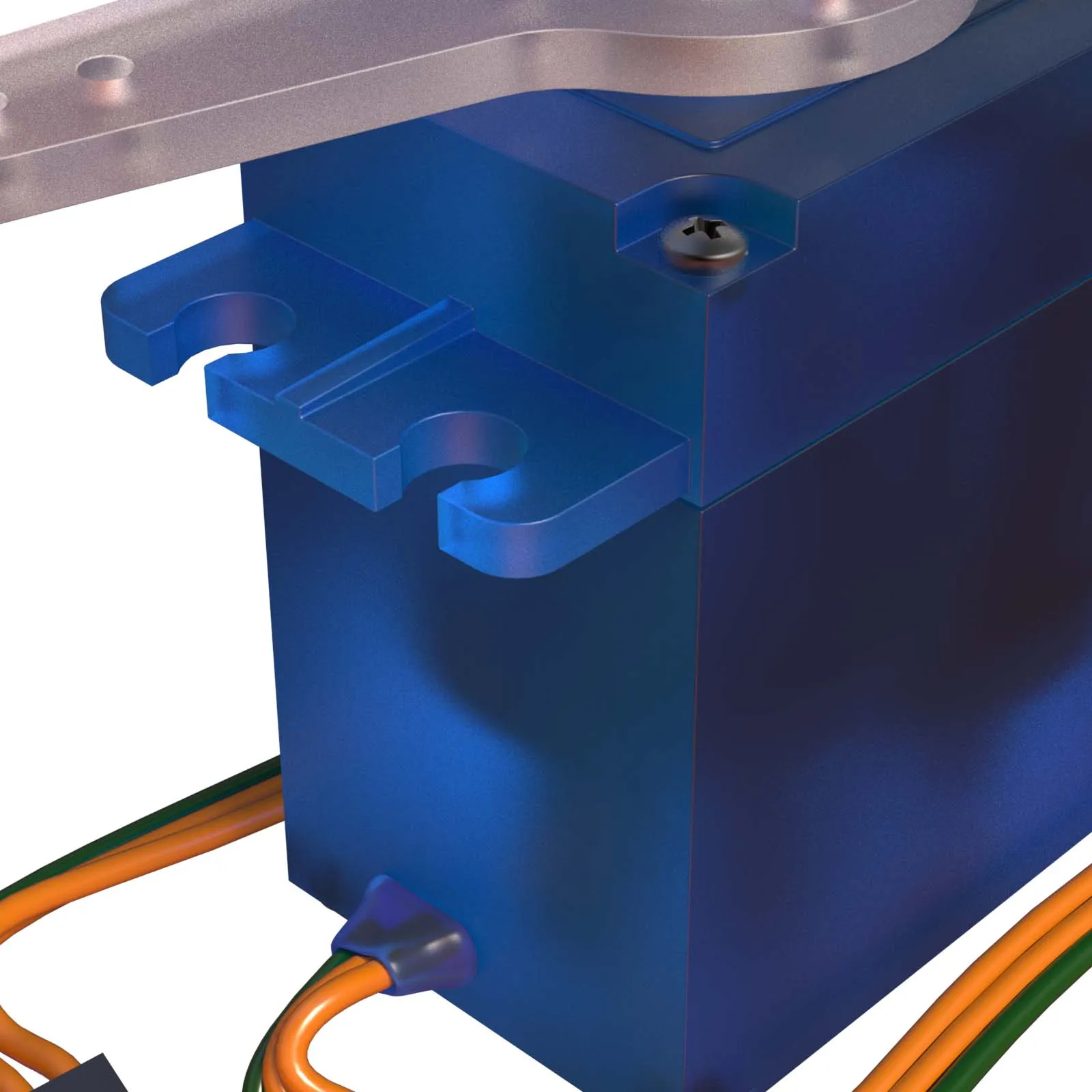

Precision Control: Servos offer precise control over the movement of RC model components, allowing for accurate positioning and responsiveness to user inputs from the transmitter/controller. This precision is crucial for achieving smooth and stable flight or operation of the RC model.

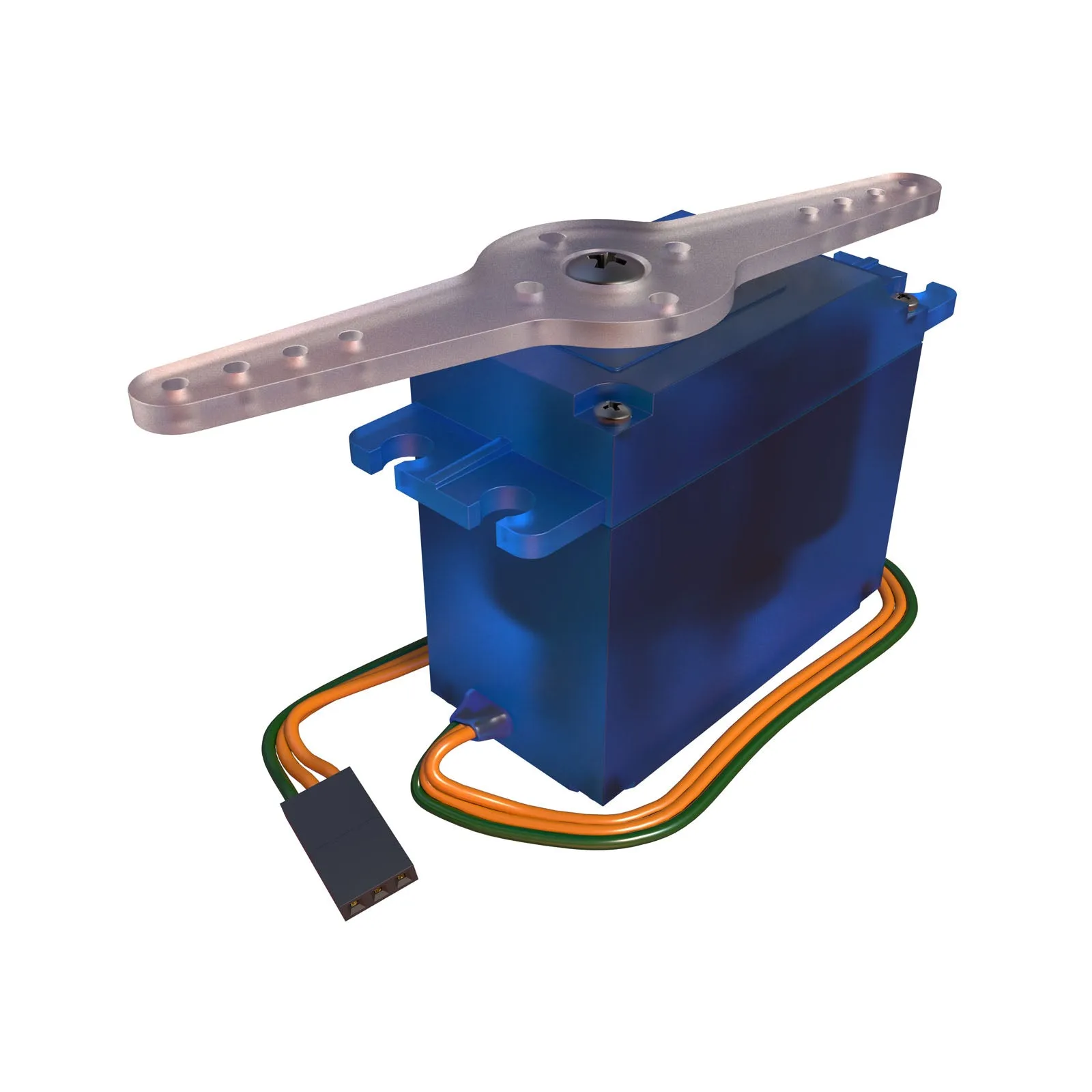

Torque: Servos come in various torque ratings to suit different applications and loads. Higher torque servos are capable of exerting greater force and are suitable for controlling heavier components or performing tasks that require more power, such as steering large RC cars or controlling retractable landing gear in airplanes.

Speed: Servos have different speed ratings, indicating how quickly they can move between positions. Higher speed servos are desirable for applications where rapid response and agility are required, such as aerobatic maneuvers in RC airplanes or fast steering corrections in RC cars.

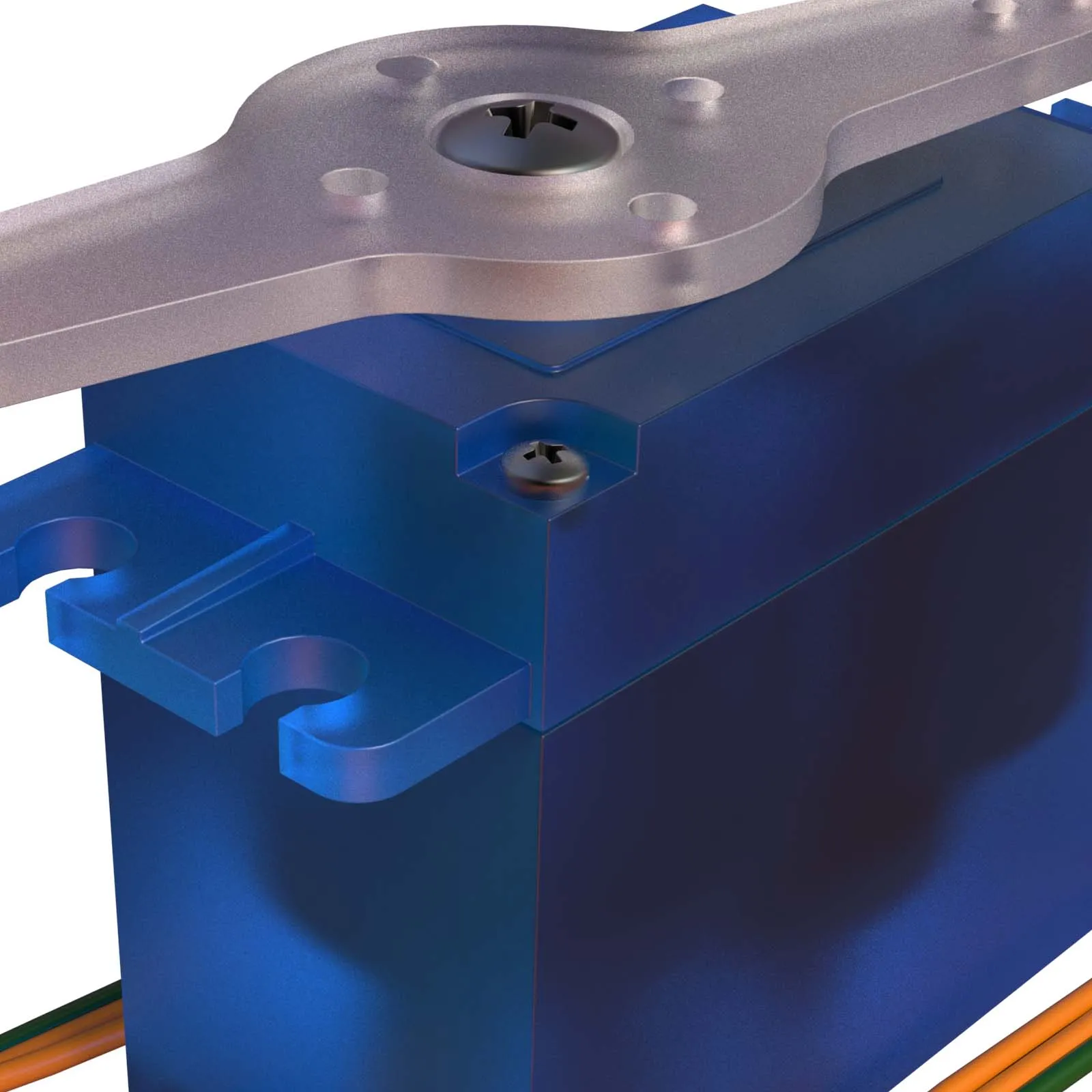

Size and Weight: Servos come in different sizes and weights to accommodate the space constraints and weight distribution requirements of different RC models. Micro servos are small and lightweight, making them ideal for smaller RC aircraft or vehicles, while standard and large servos offer higher torque and are suitable for larger models.

Overall, servos play a crucial role in RC modeling by providing precise and reliable control over the movement of different components in RC vehicles and aircraft. Whether you're steering a car, controlling the throttle of a plane, or operating the flaps of a drone, servos are essential for achieving smooth, accurate, and responsive control of your RC model.